By DeSimone Consulting Engineering (Danilo Nanni)

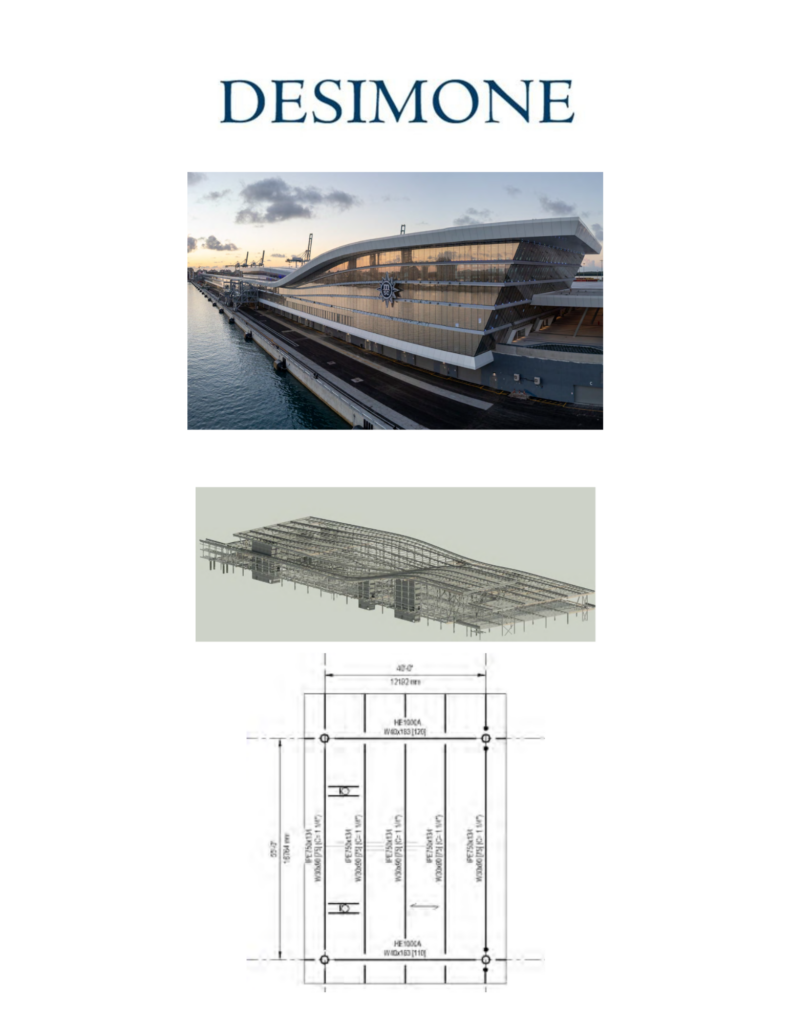

The MSC Cruise Terminal has been formally inaugurated with the Ribbon Cutting Ceremony on April 5, 2025, and is already being celebrated in many ways, primarily as the largest cruise terminal in the world, capable of handling three vessels at the same time—the equivalent of 36,000 passengers per day.

This is remarkable, but I feel that this is actually a hidden engineering gem, a premium example of American Italian collaboration in structural engineering, in this case using steel construction.

The steel columns and beams that form the structure of the terminal were completely fabricated in Italy and shipped to Miami to be assembled ‘in situ’ and then inspected by licensed American inspectors.

The entire structure has been modelled with a program called REVIT to define the actual size of each individual structural element for precise fabrication and construction.

The entire project, from a structural perspective, is kind of bilingual.

Throughout the construction document phase of the project, Italian steel section sizes and SI unit dimensions were paired with their equivalent US steel section sizes and US units. This streamlined the coordination between Italian steel fabricators and the US construction crew and ensured an unencumbered project approval by the city of Miami-Dade.

A few notes on the technical site: Per the European standard EN 10025, the Italian steel grade was S355 with 355 MPa yield strength. The equivalent of that according to the US ASTM standard was A992 with 345 MPa strength.

To ensure scalability and ease of construction of the approximately 3,000 steel beams, DeSimone limited the different types of sections to only 22 profiles and their equivalent US sections based on similar bending capacity—despite the slight difference in material grades.

We extend additional credit for the structural design to DeSimone Managing Principal William O’Donnell and Principal Ahmed Osman.